ENCAPSULATION

PROTECTIVE COATING

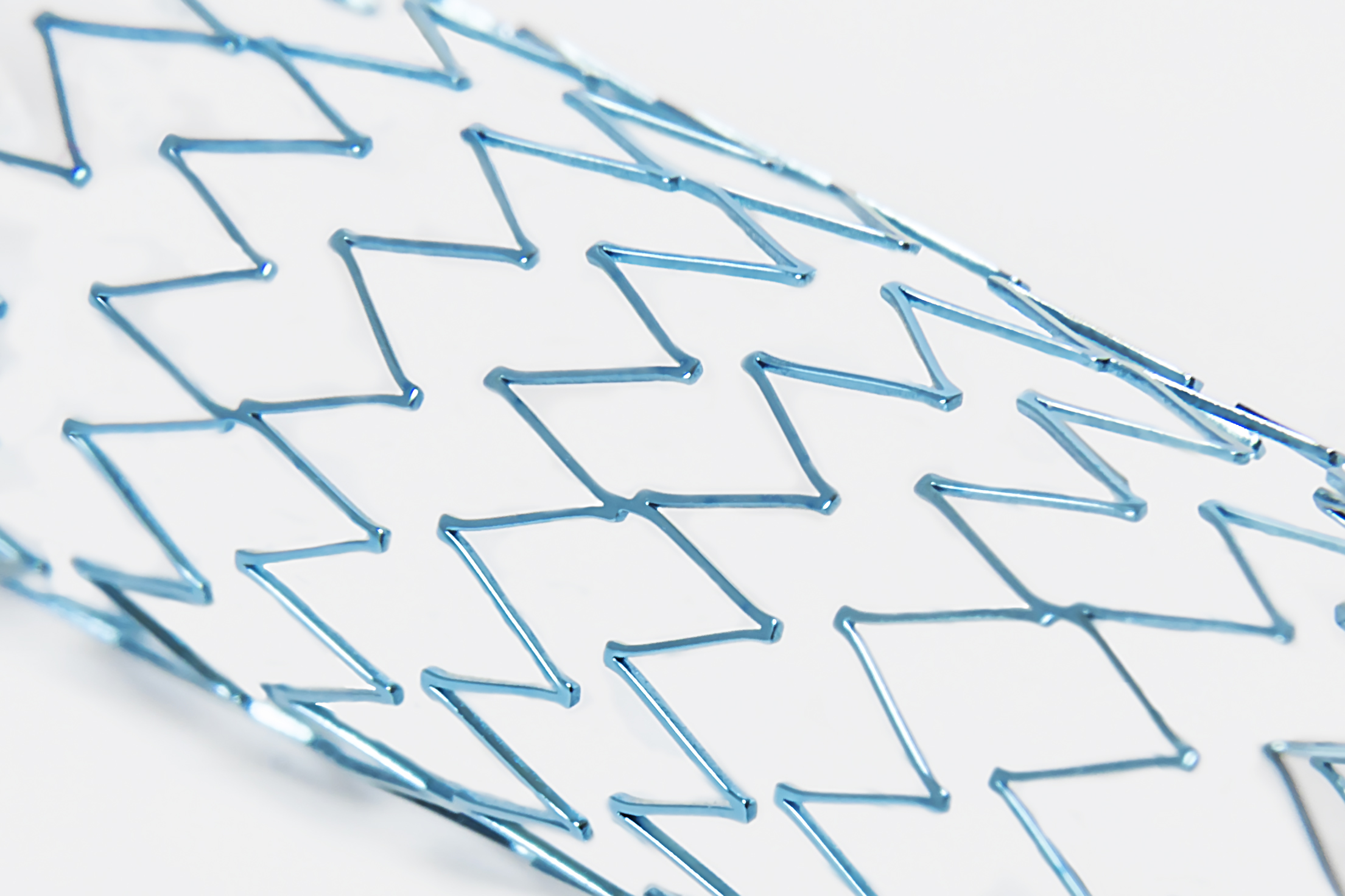

Encapsulation of parts is used to protect medical implants from bodily fluids, and prevent implant particles from escaping into the body. The ultra-thin films provided by POSITIVE COATING are perfectly suited to encapsulation of highly corrosive materials, and miniaturised electronics which require a reliable protection method. This process prevents implanted devices from corroding under physiological attack, and protects the patient from allergic reactions and rejections caused by reaction to a foreign body. In addition, this hermetic sealing safeguards the patient from any release of toxic metal ions from the implant. These encapsulation properties can also be improved by combining POSITIVE COATING coatings with other technologies, so as to create multi-layers.

STRONG POINTS

- USED TO PROTECT MEDICAL IMPLANTS FROM BODILY FLUIDS

- ULTRA-THIN, BIOCOMPATIBLE, DENSE AND IMPERMEABLE LAYERS Prevents implant particles from escaping into the body (any release of toxic metal ions from the implant)

- EXCELLENT RELIABILITY OF PROTECTION FOR HIGHLY CORROSIVE MATERIALS AND MINIATURISED ELECTRONICS

Protects the patient from allergic reactions, and rejections caused by reaction to a foreign body

- EXCELLENT CHEMICAL STABILITY

- APPLICABLE TO A WIDE RANGE OF MATERIALS such as stainless steel, Nitinol, cobalt-chromium alloys, titanium alloys, ceramic, polymers, and many more

- THESE ENCAPSULATION PROPERTIES CAN BE IMPROVED BY COMBINING OUR COATINGS WITH OTHER TECHNOLOGIES, IN ORDER TO CREATE MULTI-LAYERS.

INTERNAL

COMPLEX-GEOMETRY PARTS

PROTECTION AGAINST CORROSION AND TARNISHING

REVERSIBLE PROCESS

VERY GOOD CORROSION RESISTANCE

EXCELLENT CHEMICAL STABILITY

COMPOSITION: metal oxides

THICKNESS: 0.1 µm (+/- 15%)

DEPOSITION TEMPERATURE: ~150 °C

HARDNESS: ~600 Hv